ECON oxygen gas analyzer

for work at temperatures from +25 to +760 оС

The stationary gas-analytical device for determining the oxygen level of ECON is designed for continuous remote non-sampling measurement of oxygen content in the gaseous media of technological plants operating on various types of hydrocarbon fuels (natural gas, fuel oil, coal, shale), as well as in various inert gaseous media. The complex is designed to operate as an independent control device, & nbsp; and as part of automated combustion control systems.

The gas analysis device is manufactured in accordance with TU 95-2468-2000 and consists of a sensor installed directly in the measurement zone, an electronics unit that generates a unified signal proportional to the oxygen content in the exhaust gases, a connecting cable up to 80 (eighty) meters long, set of connecting wires and spare parts kit.

The gas analytical device is a measuring instrument (Certificate RU.С.31.147.A. No. 35763 dated 08.28.2014) and is intended to be used both as an independent control unit and as a primary converter in automated operating mode control systems technological installations.

The sensor is located in a special technological hole of the installation, for example, in a chimney, in a boiler shunt pipe, in the area of a superheater, on the regenerator arch, or in other places of a fuel-burning device.

The sensing element is located directly in the measuring area. This arrangement of the sensitive element eliminates the need to use a sampling system, and also allows for high accuracy of readings and rapid response to changes in the analyzed medium. The design of the ceramic sensitive element element is an original development RPE "ECON" (patent for invention No. 2339028), designed for maximum measurement accuracy, reliability and durability.

FEATURES OF CONSTRUCTION OF A SOLID ELECTROLYTE SENSITIVE ELEMENT

The design of the ceramic sensing element is an original development of JSC ECON, designed for maximum reliability, accuracy and durability.

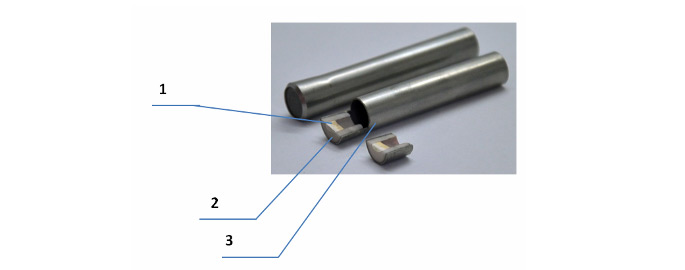

The structure of solid electrolyte sensitive elements ECON

- solid electrolyte based on zirconia ZrO2

- magnesia spinel insulator MgAl2O4

- stainless steel case (vacuum tight connection)

A high level of reliability of the gas analyzer, its accuracy and speed is ensured by an original design solution: a composite solid electrolyte sensing element (solid electrolyte made of zirconium dioxide ZrO2, in an insulator made of aluminum-magnesium spinel MgAl2O4, hermetically sealed in a stainless steel tube) is permanently fixed, permanently fixed, non-removably fixed sensor operating temperature of 750 ± 1 degree. A solid-electrolyte sensing element of our own design and production is mounted on the end of the immersion part of the probe with a length of 200 to 2000 mm and is located directly in the analyzed medium. The solid electrolyte sensing element is protected from the dust contained in the exhaust gases by an easily removable blown ceramic filter (in-house development and production).

This design solution provides the following benefits:

- The optimal working temperature of the solid electrolyte sensing element (750 0С) provides high performance due to an increase in the rate of processes in the solid electrolyte and increased accuracy by eliminating the influence of impurities of combustible gases in the test medium on oxygen readings.

- High level of protection of the sensitive element from the effects of aggressive environment and temperature (even in the case of microcracks in ceramics, the sensor does not lose metrological characteristics and is guaranteed to remain operational).

- The constantly maintained working temperature of the solid electrolyte sensing element (750 0С) ensures a long service life and accuracy of readings regardless of the temperature of the controlled medium.

- The location of the sensitive element directly in the analyzed medium provides a high level of gas analyzer speed (T0.9 = 10 seconds) and measurement continuity.

- Refusal of sampling, preparation and delivery of sampling systems, which can significantly reduce the labor costs for maintenance, increasing service intervals and minimizing the number of necessary procedures.

- The life of a solid-electrolyte sensitive element of an ECON stationary oxygen analyzer is from 5 (Five) to 10 (Ten) or more years (depending on the type of fuel used).

The original design of the sensitive element allows the device to operate smoothly and efficiently in transient conditions (gas - fuel oil, coal - fuel oil).

The electronic unit is connected to the sensor using a heat-resistant cable up to 80 meters and shows the current value of oxygen concentration and temperature of the sensor.

The electronic unit generates a unified signal 0-5 and 4-20 mA , proportional to the oxygen content in the controlled gas. Optionally, the unit can be equipped with an additional interface (RS 485) for integrating the device into industrial networks, and solving problems within the framework of the existing process control system, or for building this system from scratch using the ECON gas analyzer.

EXECUTIONS OF GAS ANALYZERS OF THE ECON SERIES

WITH CURRENT OUTPUT (0 - 4; 5 - 20 mA). The tool of visual control, manual and automated process control. The electronics unit is equipped with a display and a unified current output of 0 - 5 mA and 4 - 20 mA. This allows you to visually control the parameters and control the process in manual mode, or connect the device to the recorder, data acquisition system or ACS. The best application is boiler rooms and separate mini-CHP plants of industrial enterprises.

With RS-485 (Optional). The electronics unit is additionally equipped with an RS 485 interface to integrate the device into industrial networks and solve problems within the existing process control system, or to build this system from scratch »Using an ECON gas analyzer. An ideal solution for large enterprises using a large number of devices connected (or planned to be connected) into a single automated system.

TROPICAL modification is designed for operation of ECON oxygen gas analyzers in a tropical climate. The solutions used in this modification guarantee the trouble-free operation of the gas analyzer in conditions of high humidity and high ambient temperatures. Tropical ECON gas analyzers have been successfully used at Siddirganch TPP (TPP Siddhirganj) in the Republic of Bangladesh since 2010.

EKON gas analyzers can successfully perform measurements both in transition periods (when using fuel oil) and in conditions of high dust content (up to 100 g / m3). This is possible due to design features and solutions, including the use of a replaceable ceramic filter with the ability to purge it without removing the sensor.

RPE "ECON" can equip its gas analyzers not only with ceramic filters (standard equipment), but also with porous stainless steel filters (optional). Filters made of porous stainless steel have increased strength and wear resistance under the conditions of abrasive action of mechanical particles in the gas phase. ECON sensors can be equipped with such filters, for example, for operation on dust preparation lines, in conditions of increased dust content of flue gases. Corrosion-proof filter - replaceable, purged, interchangeable with a ceramic filter, replacement can be done by service personnel. The stainless filter can be supplied to the customer additionally, under a separate contract, or as part of an ECON gas analyzer sensor.

Ceramic and metal filters of the sensor of the ECON gas analyzer

The characteristics of the device are indicated in the table "The main technical characteristics of the gas-analytical device EKON" and in the table "The main design characteristics of the gas-analytical device ECON".

PROTECTIVE REPLACEMENT FILTERS

Special option for ECON gas analyzers: filters made of porous stainless steel (optional; on request). Filters of this type (see photo "EKON filter made of porous stainless steel") have a significantly higher degree of strength and wear resistance to abrasive mechanical particles in the gas phase than ceramic ones.

Filters made of porous stainless steel are suitable for use in dusty flue gas environments. Corrosion-proof filter - replaceable, purged, interchangeable with a ceramic filter (see photo "Ceramic filter and a filter made of porous stainless steel") filter. Replacements may be made by service personnel. It is delivered optionally to the customer.

Photo "ECON filter made of porous stainless steel"

Photo “Ceramic and porous stainless steel filters”

The design developed by RPE ECON provides an unprecedentedly high level of reliability of a solid electrolyte sensing element, which does not need to be replaced during the entire life of the sensor.

The service life of the sensor is from 5 (flue gas analysis of HPS on fuel oil) to 10 and more years (HPS on gas).

The main technical characteristics of the gas analytical device ECON

| Controlled Environment Parameters |

| The oxygen content in the analyzed gas mixture,% vol. |

0,1 ... 25,0 |

| Controlled Temperature, 0С |

25 ... 760 |

| Pressure of the controlled environment (excess), kPa |

from - 3.9 to + 4.4 |

| The flow rate of the controlled environment, m/s |

0 ... 15 |

| Dustiness of the controlled environment, g/m3 |

up to 100 |

| Ambient temperature (sensor terminal head), 0С |

- 30 ... + 70 |

| Ambient temperature (electronic unit), 0С |

+ 5 ... + 50 |

| Relative humidity, % |

up to 95 at t = 350С |

| The limit of permissible basic measurement error |

| in the measuring range No. 2, 3 |

2,5% |

| in the measuring range No. 1 |

0.1% vol |

| Volume measurement ranges О2 |

| 1 range, % vol. |

0,1 ... 2,5 |

| 2 range, % vol. |

0,1 ... 5,0 |

| 3 range, % vol. |

0,1 ... 10,0 |

| 4 range, % vol. |

0,1 ... 25,0 |

| Output signal |

| Settling time 90% of signal T0,9d, с |

10 |

| Power supply 220V, 50Hz, power consumption W, no more |

150 |

| Mass of the electronic unit, kg, no more |

5 |

The warranty period is 2 (Two) years.

The time interval without calibration is 1 (One) year.

The average life of the gas detector sensor is at least 5 (Five) years , the electronics unit - 10 (Ten) years .

Main structural characteristics of the gas-analytical device ECON, modification of EC

| Parameter |

Size |

| А |

B |

C |

D |

E |

F |

| The length of the immersion of the sensor, mm |

340 |

500 |

800 |

1000 |

1270 |

2000 |

| Total length of the sensor, mm |

620 |

780 |

1080 |

1280 |

1550 |

2280 |

| Diameter of the immersion part of the sensor, mm |

57 |

| Diameter of sensor mounting flange, mm |

140 |

| Sensor weight, kg |

3,1 |

3,5 |

4,3 |

4,7 |

5,5 |

7,6 |

| The length of the connecting cable between the sensor and the electronics, m |

30 (optionally up to 80) |

| Cable length from electronic unit to information receiver, m |

300 |

The gas analyzer sensor is mounted using an installation flange with a diameter of 140 mm (DN50 PN1, GOST R No. 54432-2011, DIN 2501).

ECON oxygen gas analyzer sensor device

1 - sensor body, 2 - sensor, 3 - heater, 4 - flange, 5 - screen shell, 6 - terminal flange, 7 - nipple connector, 8 - CGM tube, 9 - CGM tube cover, 10 - replaceable ceramic filter (or filter made of porous stainless steel)

Advantages of gas analytical devices ECON

- ECON gas analysis instruments are reliable and simple & nbsp; means for measuring the level of oxygen in the exhaust gases of boiler units.

- High level of reliability, speed, accuracy of measurements and indications, achieved by:

• location of the sensitive ceramic element directly

in the analyzed medium;

• lack of a sampling and preparation system;

• use of a sensitive ceramic element of our own design and production (patent No. 2339028).

- The warranty period for the operation of the gas analyzer is 2 (Two) years.

- Availability of additional services for post-warranty servicing of devices (ensures the maximum useful life of each piece of equipment).

At JSC "ECON", a multi-stage quality control system has been introduced, including:

- Incoming inspection of all incoming materials and elements;

- Multistage control of a solid electrolyte sensitive element at all stages of the production cycle;

- Control of production processes, ensuring compliance with all technical regulations and processes;

- Total output control of ceramic elements;

- Total output control of individual units and the gas analyzer as a whole.

ECON gas analyzers are innovative, high-tech devices that have proven reliable, durable and easy to use. Thousands of fuel-burning enterprises have opted for ECON gas analysis instruments. Nearly two thousand boiler units and fuel-burning plants are equipped with ECON stationary oxygen meters (see reviews).